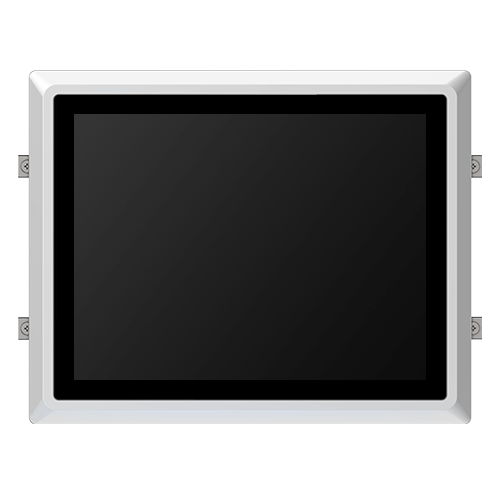

Industrial automation needs displays that work well in tough places. Industrial touch screens are made with strong materials. They can handle very hot or cold temperatures, shaking, dust, and water. These screens still work even if they are dropped or hit. Their smart touch features make them easy to use. This helps people control machines better. Clear visuals help users understand data quickly and correctly. This improves how well systems work. Custom designs and flexible setups let these screens change as industries grow. This makes them very important for today’s factories.

Durability and Strength in Industrial Automation TouchScreens

Industrial touch screens are made to survive tough conditions. They are important for automation because they are strong and reliable. Let’s look at what makes these screens tough and trustworthy.

Handling Shock, Vibration, and Extreme Temperatures

These screens can handle physical stress like shaking or impacts. They keep working even in rough environments without stopping. Many meet MIL-STD-810G standards, proving they survive harsh conditions. For example, rugged tablets like the ValanoIPC IP105-150 work in extreme heat or cold. They also perform well under heavy vibration, making them great for smart factories.

Their sturdy design helps them work in freezing warehouses or hot factories. These screens stay reliable no matter the temperature. This reduces downtime and keeps systems running smoothly.

Protection Against Dust and Water

Industrial touch screens often have high IP ratings for dust and water safety. The IP system, based on EN 60529 standards, uses numbers to show protection levels. For example:

| IP Rating | What It Protects Against |

|---|---|

| IP65 | Keeps out dust and blocks water jets. |

| IP67 | Keeps out dust and handles water up to 1 meter deep. |

| IP68 | Keeps out dust and works underwater for long periods. |

Built to Last and Stay Reliable for Industrial Automation

Good quality industrial touch screens are made to last a long time. Features like scratch-proof surfaces and tough panels prevent damage. Fanless designs avoid mechanical problems, making them perfect for dusty areas.

Many screens come with warranties for extra confidence in their durability. Their advanced touch features make them easy to use, improving machine control. These qualities make them a smart choice for automation systems.

Easy-to-Use Touchscreen for Industrial Automation Systems

Industrial touch screens with simple interfaces are key for modern factories. They make tasks easier, improve user experience, and boost screen performance. This makes them very useful in smart manufacturing.

Types of Touch Technologies (Resistive, Capacitive, Projected Capacitive)

Touchscreen tech has improved to fit different factory needs. The three main types—resistive, capacitive, and projected capacitive—each have special features for various uses.

| Feature | Capacitive | Resistive |

|---|---|---|

| How it works | Light touch (conductive) | Pressure touch |

| Cost | More expensive | Cheaper |

| Touch sensitivity | Very sensitive | Less sensitive |

| Screen clarity | Best | Good |

| Durability | Best | Good |

| Multi-touch ability | Yes | No |

| Works with gloves or stylus | Limited | Yes |

| Best for | Precise tasks | Tough environments |

Projected capacitive screens are great for precise, multi-touch tasks in advanced factories. Resistive screens work well in rough places where toughness matters most.

Easier Navigation, Fewer Extra Devices

Simple touchscreens reduce the need for keyboards or mice. Better menu designs and understanding how people think make navigation faster.

Research shows that simpler menus improve accuracy and allow hands-free use. This cuts down on extra devices, making work smoother in factories.

With fewer tools to handle, workers can focus better on controlling systems. This increases efficiency.

High-Resolution Display for Industrial Automation

Industrial automation needs screens that show clear and sharp images. High-resolution displays help users control systems better and work faster.

Why Brightness and Anti-Glare Matter

Brightness and anti-glare features make screens easier to read. They help users see important details in any light, indoors or outdoors.

| Feature | Why It’s Important |

|---|---|

| Good Contrast | Makes screens readable in different lighting conditions. |

| Adjustable Brightness | Lets users change brightness for indoor or outdoor use. |

| Anti-Glare Coating | Reduces glare from sunlight or bright lights for better visibility. |

Clear Visuals for Better Work

Clear visuals help workers spot problems, check systems, and improve processes. Sharp images and videos make work more accurate.

| Evidence Type | What It Shows |

|---|---|

| Faster Operations | Clear visuals speed up how systems are managed. |

| Better Quality Control | Helps find and fix product issues quickly. |

| Higher Productivity | Improves overall work output in factories. |

High-resolution screens boost productivity and keep systems running smoothly. These displays are a must-have for modern factories.

Connectivity Options in Industrial Automation Touch Screen Monitors

Industrial touch screen monitors help connect systems and improve factory work. Their features make it easy to link with automation tools. This boosts how well machines work and keeps them reliable.

Support for Communication Protocols (Ethernet, Wi-Fi, Cellular)

Modern monitors use different ways to connect, like Ethernet, Wi-Fi, and cellular. Ethernet gives fast and steady connections for local networks. Wi-Fi lets devices talk wirelessly, cutting down on cables. Cellular is great for places where regular networks don’t work.

These options keep monitors connected to important systems anywhere. For example, Wi-Fi monitors share data quickly between teams. Cellular monitors work well in faraway places, even in tough conditions.

Integration with Existing Industrial Automation and Control Systems

Industrial monitors easily connect to current control systems. They are built to fit small setups or big factory networks. This makes it simple to improve operations without changing everything.

| Feature/Capability | Description |

|---|---|

| Networks and Security Updates | Updates improve safety and keep systems running smoothly. |

| Plant-wide Control and Optimization | Combines different controls into one system for better results. |

| Scalable and Modular Architecture | Works for small or large setups, making integration easy. |

These features keep systems safe, flexible, and ready for new challenges. By connecting monitors to existing systems, factories can save resources and work better.

Remote Monitoring and Control Capabilities

Remote monitoring changes how factories check and control machines. Sensors connected to the internet track equipment in real time. This helps find problems early and plan repairs, reducing downtime.

Big companies use smart systems to predict problems before they happen. Machine learning tools analyze data to keep machines running longer. Companies like Boeing and NASA have seen big improvements using these systems.

With remote monitoring, factories can save money, work faster, and avoid delays. These tools are key for modern manufacturing success.

Advanced Customization and Scalability for Industrial Applications

Factories need tools that fit their tasks and can grow. Customization and scalability in touch screens help meet these needs.

Custom Interfaces for Specific Tasks

Custom screens make work easier by fitting your tasks. For example, small companies adjust to meet big client needs. Systems like Just-In-Time (JIT) help improve operations and solve problems.

Studies show custom software boosts efficiency by 25%. These screens also follow strict rules, lowering risks. By customizing touch screens, factories work better and stay competitive.

Modular Design for Easy Fixes

Modular designs make upgrades and repairs simple. Touch screens with modular parts are easy to fix, saving time. Better connectors and less interference help them work with new tech.

| Benefit | What It Does |

|---|---|

| Easier Repairs | Quick part changes and easy access. |

| Better Flexibility | Works well with new technologies. |

| Improved Cooling | Saves energy with better heat control. |

| Smart Problem-Solving | Remote checks find and fix issues faster. |

This design keeps systems running smoothly and ready for new challenges.

Scalability for Growing Needs

Scalability helps factories handle more work. Touch screens with 5G and Wi-Fi 6 share data fast. Energy-saving screens work well in remote areas.

| Metric | Value |

|---|---|

| Market Size by 2028 | $1.6 billion |

| Market Size in 2023 | $0.9 billion |

| Growth Rate (2023-2028) | 13.3% |

Scalable systems use IoT and smart tools to boost production. Predictive tools make work faster and smarter. These screens help factories grow and stay ahead in the market.

Industrial automation needs screens that are tough and easy to use. They should show clear images, connect well, and be customizable. These features help systems work better and adjust to new needs. Picking touch screens with these abilities makes processes faster and easier to control. Custom options solve specific problems and improve efficiency. Focus on these features to get systems that last long and fit smoothly into your work.