Choosing the right device for industrial operations is crucial, and understanding the differences between Industrial Rugged Tablets vs Panel PCs can help businesses make informed decisions. Each option offers unique advantages in durability, mobility, and functionality, impacting productivity and operational efficiency. This guide explores when to select a rugged tablet or a panel PC, helping teams match the right technology to their specific industrial applications.

Industrial Rugged Tablets vs Panel PCs Comparison

Key Features Overview

The main differences between industrial tablets and panel pcs appear in their design and function. Industrial tablets focus on mobility and battery-powered use. Panel pcs offer fixed installation and continuous power.

| Feature | Industrial Rugged Tablets | Industrial Panel PCs |

|---|---|---|

| Power Source | Battery-powered | Hardwired, continuous |

| Durability | High, portable rugged | High, stationary rugged |

| Lifespan | Moderate to long | Long, with less movement |

| Integration | Wireless, flexible | Direct with machinery |

| Performance | Good for mobile tasks | High for fixed tasks |

Panel pcs connect directly to industrial equipment. They support many input and output options. Industrial tablets use wireless connections and work well in changing locations.

Typical Use Cases

Industrial tablets suit workers who move between sites. Field technicians, warehouse staff, and construction crews use these rugged devices for data collection and inspection. The tablets help in environments where flexibility and portability matter most.

Panel pcs fit best in production lines, monitoring stations, and control rooms. Operators use these rugged computers for machine control and process monitoring. Panel pcs excel in places that need continuous operation and direct integration with industrial systems.

Industrial tablets work well in outdoor or remote areas. Panel pcs perform best in fixed, indoor industrial settings. Each device supports different workflows based on mobility and integration needs.

Choosing Industrial Rugged Tablets

Mobility and Flexibility

Industrial tablets offer unmatched mobility for workers who move between locations. Field technicians often carry rugged industrial tablets to job sites, where they collect data and update records on the go. These devices support rotating workstations and mobile applications, making them ideal for teams that need flexibility.

Many industrial tablets feature wireless connectivity, which supports real-time communication and data transfer. Workers can use reliable computer tablets in warehouses, construction zones, or outdoor sites. The all-in-one industrial computer design ensures that users have access to essential tools wherever they go.

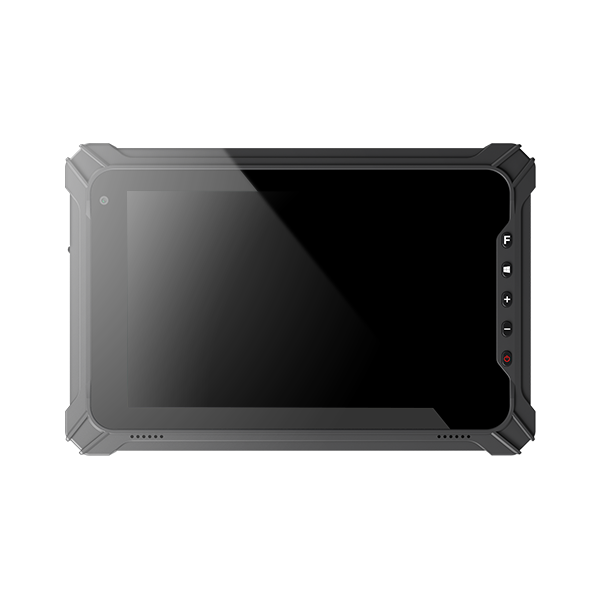

Durability in Harsh Conditions

Rugged industrial tablets stand out for their durability in harsh environments. Manufacturers build these devices with ruggedized construction and reinforced casings to protect against drops, dust, and water. Industrial tablets often meet strict standards for environmental protection, which ensures reliable operation in extreme temperatures or wet conditions.

The rugged design extends the mean time between failures, which means fewer repairs and less downtime. Many industrial tablets come with longer warranties, reflecting their robust build and expected lifespan. These features make rugged tablets a cost-effective choice for industries that require dependable equipment.

Battery Life and Portability

Battery life plays a key role in the performance of industrial tablets. Workers can use these devices for long shifts without needing to recharge frequently. The portability of rugged tablets allows users to carry them easily between tasks or locations.

Rugged industrial tablets often include hot-swappable batteries, which further reduces interruptions. The combination of portability and strong battery performance makes these tablets suitable for applications that demand constant movement. Many organizations choose industrial tablets for their ability to deliver reliable service in the field, backed by a solid warranty and industrial-grade motherboard.

| Feature | Benefit |

|---|---|

| Mobility | Supports fieldwork and rotating teams |

| Durability | Withstands harsh environments |

| Battery Life | Enables long, uninterrupted use |

| Cost-Effectiveness | Reduces downtime and repair costs |

| Warranty | Offers longer warranties for peace of mind |

Rugged industrial tablets provide a smart investment for companies that need tough, portable, and reliable devices. Their rugged features, strong protection, and industrial focus help maintain productivity and operational efficiency in challenging settings.

Choosing Panel PCs

Fixed Installation Needs

Panel pcs work best in environments that require stationary computing. Many factories and plants install these devices on walls or machinery. The hardwired power source ensures continuous operation and reduces the risk of downtime.

Panel pcs provide strong protection against dust and moisture. Their rugged enclosures help them last longer in industrial settings. Companies often choose panel pcs for tasks that do not need mobility.

Integration with Machinery

Panel pcs connect directly to industrial equipment. These devices offer a wide range of industrial I/O options, such as serial ports and USB interfaces. Operators use panel pcs to control machines and monitor processes.

Panel pcs support industrial applications that demand precise data exchange. The seamless integration improves reliability and reduces errors. Many production lines rely on panel pcs for real-time monitoring and control.

Continuous Operation

Panel pcs run on hardwired power, which allows them to operate without interruption. Many monitoring stations and control rooms use panel pcs for 24/7 tasks. The devices handle demanding workloads and support industrial applications that require constant attention.

Panel pcs offer long-term reliability and often come with extended warranty options. Their robust design helps prevent downtime and ensures consistent performance. Companies trust panel pcs for critical operations where failure is not an option.

| Application Area | Benefit of Panel PCs |

|---|---|

| Production Lines | Continuous monitoring |

| Control Rooms | Reliable data display |

| Monitoring Stations | Stable operation |

| Machinery Integration | Direct equipment control |

Panel pcs deliver dependable service in industrial environments. Their stationary use, strong protection, and integration features make them ideal for fixed installations.

Decision Checklist for Industrial Tablets and Panel PCs

Environment Assessment

Decision-makers should start by evaluating the industrial working environments. They need to check for exposure to dust, moisture, and vibration. Ruggedized construction offers protection in harsh industrial settings. If the workspace changes often or includes outdoor areas, tablets may suit the job. Panel PCs work best in fixed locations with stable conditions.

Workflow and User Needs

Teams should list the main tasks and applications required. Workers who move between stations or need to collect data on the go benefit from tablets. Panel PCs support operators who control machinery or monitor processes in one place. Consider the need for touchscreens, barcode scanning, and wireless connectivity. Review operating system compatibility and storage needs for each role.

| Device Type | Best For | Key Features |

|---|---|---|

| Rugged Tablet | Mobile workflows | Wireless, portable, flexible |

| Panel PC | Stationary operations | Hardwired, integrated, robust |

Budget and Maintenance

Companies must compare initial costs and long-term expenses. Tablets may cost less upfront but require battery replacements. Panel PCs offer longer lifespans in stationary industrial settings. Maintenance needs differ based on device movement and exposure. Performance requirements also affect cost, especially for demanding industrial applications.

Step-by-Step Device Selection Guide

- Assess the industrial environment for hazards and mobility.

- Identify workflow needs and required applications.

- Check compatibility with existing systems and storage requirements.

- Compare costs, maintenance, and warranty options.

- Choose the device that matches the industrial setting and long-term goals.