What is LED Technology and Why is it Ideal for Industrial Displays?

LED stands for Light Emitting Diode, a semiconductor device that emits light when an electric current passes through it. Unlike traditional display technologies like LCD (Liquid Crystal Display) or CRT (Cathode Ray Tube), LED technology uses solid-state lighting, making it more energy-efficient and durable. In an Industrial LED Display Monitor, this technology offers superior brightness, low power consumption, and longer life, which are essential for demanding industrial environments.

ED vs. LCD vs. CRT: Key Differences for Industrial Displays

| Attribute | LED | LCD | CRT |

|---|---|---|---|

| Energy Efficiency | High (low power consumption) | Moderate (higher than LED) | Low (high power consumption) |

| Lifespan | 50,000 – 100,000 hours | 30,000 – 60,000 hours | 20,000 – 30,000 hours |

| Display Quality | Superior brightness, contrast, and color accuracy | Good, but struggles with brightness and contrast | Good, but lacks clarity and brightness |

| Durability | Highly durable, impact and temperature resistant | Fragile, more prone to damage | Most fragile, sensitive to impacts and temperature |

| Size and Design | Slim, lightweight, compact | Thin, but bulkier than LED | Large, heavy, and bulky |

| Cost | Higher upfront, lower long-term costs | Moderate upfront, moderate long-term costs | Low upfront, high long-term costs due to maintenance and power consumption |

Custom Industrial LED Display Monitors

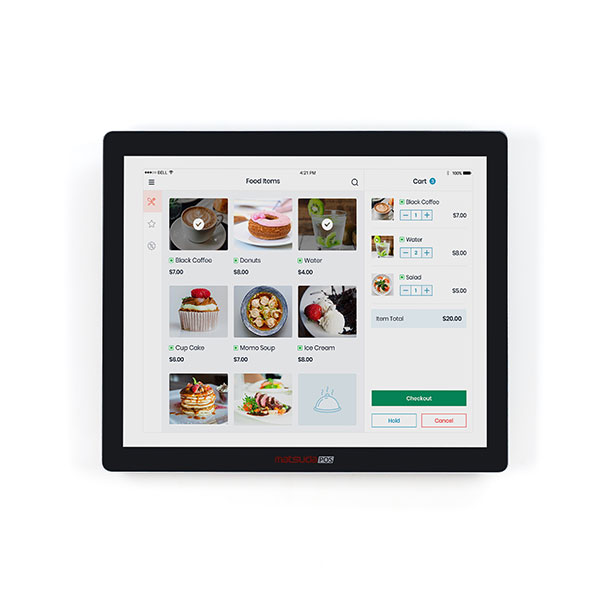

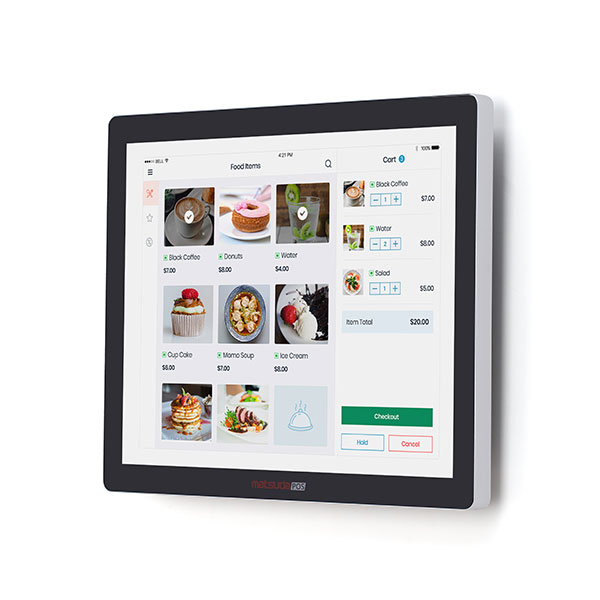

Valano’s Industrial LED Display Monitors are designed to meet the unique needs of industrial environments, offering customizable solutions for a wide range of applications.

Tailored to Your Specific Needs

Our monitors can be customized for use in various environments, including factories, warehouses, outdoor installations, and harsh industrial settings. Choose from a variety of screen sizes, resolutions, and rugged enclosures to ensure a perfect fit for your operational needs.

Flexible Mounting Solutions

The Industrial Monitors come with multiple mounting options, including VESA and wall mounts, giving you the flexibility to integrate them into your existing systems, whether in control rooms, machinery stations, or production lines.

Customized Software & Branding

Enhance functionality with custom software integration tailored to your specific applications, whether for data visualization, touch interfaces, or monitoring systems. Additionally, we offer branding options to include your company’s logo and color scheme, creating a cohesive look across your industrial setup.

Seamless Integration

Easily integrate our monitors with your existing industrial systems. Whether it’s RS232, USB, or other industrial protocols, our monitors are designed to communicate effortlessly with your machinery, control systems, and automation setups.

Maintenance of Industrial LED Display Monitors

Proper maintenance is essential to ensure the longevity and reliable performance of your Industrial LED Display Monitors. Although LED technology is known for its durability, regular care can help prevent issues and keep your displays functioning at their best. Here are some key maintenance tips:

- Regular Cleaning: Dust and debris can accumulate on the screen and around the vents, affecting visibility and cooling efficiency. Use a soft, lint-free cloth to wipe the screen regularly, and clean the ventilation areas to ensure proper airflow.

- Proper Ventilation: To prevent overheating, ensure that your LED monitors are placed in a well-ventilated area. Avoid blocking the vents or placing monitors in direct sunlight or near heat sources.

- Check for Software Updates: Some industrial monitors require software updates to optimize performance. Regularly check for any available updates to ensure your LED monitor is running the latest version of its software or firmware.

- Inspect for Physical Damage: Regularly inspect the monitor for any signs of physical damage, such as cracks, scratches, or loose connections. Addressing issues early can prevent further damage and extend the life of the monitor.

- Calibration and Configuration: Over time, the display settings (such as brightness and contrast) may need recalibration. Regularly adjust settings based on the environmental lighting conditions and specific requirements of your industrial applications.

How to Choose the Right Industrial LED Display Monitor

When selecting an Industrial LED Display Monitor, start by considering the display size and resolution to ensure clear visuals for your specific application. A larger screen and higher resolution are ideal for tasks requiring detailed monitoring. It’s also crucial to choose a monitor with strong durability, capable of withstanding vibrations, temperature extremes, and exposure to dust or moisture. Monitors with IP ratings offer extra protection for harsh environments.

Additionally, consider the brightness and contrast of the display for optimal visibility in various lighting conditions. Ensure the monitor offers the right connectivity options like HDMI, VGA, or RS232 for seamless integration with industrial systems. LED monitors are also energy-efficient, reducing power consumption and long-term costs. Finally, check for flexible mounting options, such as VESA compatibility, to fit your installation needs. With these factors in mind, you can choose a monitor that meets your industrial requirements and provides reliable performance.