Industrial computer is rapidly transforming industries worldwide, driving efficiency, innovation, and growth. As new trends emerge, technologies like AI, IoT, and automation are reshaping manufacturing, logistics, and process control.

Understanding these trends is crucial for businesses aiming to stay competitive and future-ready. In this article, we’ll explore how Industrial computer technologies are shaping the future and the key advancements you need to watch.

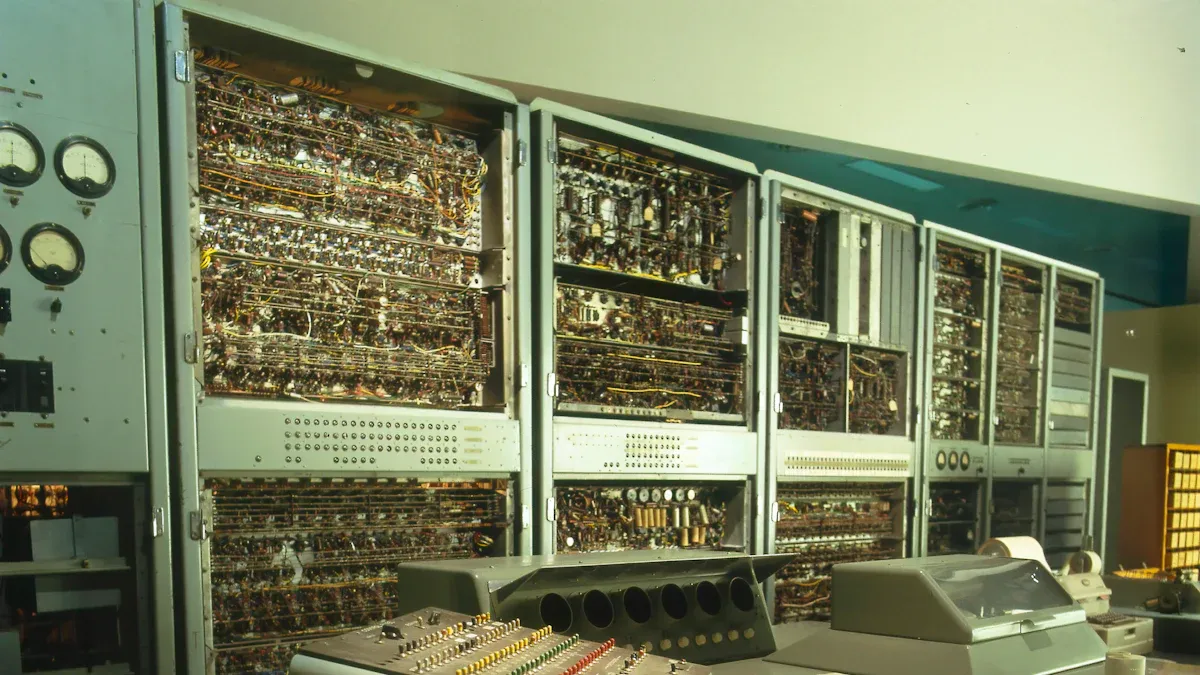

Early Industrial computer

First-gen Industrial Computers

The history of industrial computers began during the First Industrial Revolution. Factories used mechanical systems to improve production. The Second Industrial Revolution introduced electrical machines, which led to the first industrial computers. These early machines used vacuum tubes and relays to perform basic process control tasks, such as monitoring temperature and pressure.

Early Manufacturing Applications

Industrial computers became essential for process control in manufacturing. They helped automate repetitive tasks and reduced human error. Early computers managed assembly lines and chemical plants. Operators used them to collect data and adjust machinery. These systems improved efficiency, allowing factories to produce goods faster and with better quality.

Limitations and challenges

First-generation industrial computers faced many challenges. They were large, consumed a lot of energy, and often broke down. Process control systems lacked flexibility and could not adapt to changes quickly. Industrial computer technology needed more reliable components. These limitations drove engineers to develop smaller, faster, and more robust machines, laying the foundation for future advancements.

| Industrial Revolution | Key Advancement | Impact on Industrial Computers |

|---|---|---|

| First | Steam power | Mechanical process control |

| Second | Electricity | Electronic industrial computers |

| Third | Automation | Digital process control systems |

| Fourth | Connectivity & AI | Smart industrial computer technology |

Evolution of Industrial Computer Technology

Transistors and Integrated Circuits

The invention of transistors accelerated the evolution of industrial computers. Transistors replaced vacuum tubes, making machines smaller and more reliable. Integrated circuits followed, allowing engineers to place many transistors on a single chip. Industrial computers became faster, more energy-efficient, and easier to deploy across factories.

Moore’s Law & Computer Power

Moore’s Law states that the number of transistors on a chip doubles approximately every two years. This prediction guided the evolution of industrial computers for decades. Computers grew more powerful, capable of handling complex tasks, processing larger datasets, and controlling more machines.

Programmable Logic Controllers

PLCs transformed industrial automation. They replaced hardwired control panels with flexible software-based systems. Engineers programmed PLCs to control machines and processes. Industrial computers with PLCs improved safety, reduced downtime, and allowed factories to adapt quickly to new products.

PLCs offer several advantages:

- Easy to reprogram for different tasks.

- Reliable operation in harsh environments.

- Fast response to changes in production.

Modern PLCs connect to networks and share data across entire factories, showing how improvements in industrial computer hardware and software drive progress.

Advancements in Industrial computer

Industrial Networking and SCADA

Industrial networking connects machines, sensors, and controllers. Industrial computers use these networks to share information quickly. SCADA systems help operators control equipment and collect data through a human machine interface.

Real-time monitoring allows workers to see problems as they happen. Information technology supports communication between devices and people. Socio-technical systems combine technology and human roles to improve safety and efficiency.

Computer-Integrated Manufacturing

CIM links design, production, and management. Industrial computers automate tasks and track progress. Human-machine interfaces let workers interact efficiently with machines. Real-time monitoring ensures each production step is optimized. Data analytics and predictive maintenance improve quality and prevent equipment failures.

Data-Driven Decision Making

Industrial computers collect and process large amounts of information. Information technology enables trend analysis and forecasts. Real-time monitoring gives managers up-to-date reports, while predictive maintenance identifies issues early. Socio-technical systems help teams leverage data effectively.

| Technology | Role in Industry | Benefit |

|---|---|---|

| SCADA | Real-time monitoring | Faster problem solving |

| Data analytics | Predictive maintenance | Fewer breakdowns |

| Human-machine interface | Socio-technical systems | Better teamwork |

Industry 4.0 and the Future

IIoT and Smart Factories

Industry 4.0 marks a new era. Industrial computers and IIoT devices connect every part of production. Smart factories collect and process data in real time, allowing workers and managers to make quick, informed decisions. These systems reduce waste, improve quality, and enhance workplace safety.

Artificial Intelligence in Industry

AI is integrated into industrial computer systems to analyze vast datasets and detect patterns humans might miss. AI supports predictive maintenance, quality control, and operational optimization. Combined with IIoT devices, industrial computers create smarter, more flexible factories.

Future Trends and Challenges

Emerging trends for industrial computers include advanced IIoT networks, edge computing, digital twins, and industrial cloud platforms, which enable faster data processing and smarter decision-making. AI will further enhance automation, quality control, and operational efficiency, enabling truly intelligent factories.

These technological advancements also present challenges. Factories must ensure cybersecurity, integrate legacy systems with modern infrastructure, and train workers to operate increasingly complex technologies. Successfully navigating these trends is essential for industries aiming to remain competitive, efficient, and resilient in a rapidly changing landscape.

Conclusion

In conclusion, the evolution of Industrial computer technology has significantly transformed industries, driving greater efficiency, innovation, and cost savings. From the early days of process control to today’s smart factories powered by AI and IoT, these advancements enable real-time decision-making, predictive maintenance, and improved production quality.

Understanding Industrial computer trends is crucial for businesses seeking to remain competitive in the face of rapid technological change. Embracing these innovations will be key to shaping a successful, future-ready industrial landscape.