Understanding the differences between MIL-STD-810G vs MIL-STD-810H is essential for selecting rugged and reliable equipment. These military-grade standards define how devices are tested for extreme conditions like temperature, shock, and vibration. Knowing which standard applies can improve product durability, performance, and compliance. In this article, we break down the key distinctions, helping manufacturers, businesses, and consumers make informed decisions.

What is MIL-STD-810?

MIL-STD-810 describes a series of test methods that evaluate how equipment performs under harsh environmental conditions. The United States Department of Defense created this military standard to help manufacturers design products that can survive in extreme climates, rough handling, and unpredictable situations. MIL-STD-810 sets guidelines for testing temperature, humidity, shock, vibration, and other physical stresses.

Manufacturers use mil-std to check if their devices meet the requirements for military use. They follow mil-std procedures to simulate rain, dust, sand, and freezing conditions. Each test in mil-std-810 aims to mimic what equipment might face during field operations.

The mil-std process includes several steps. First, engineers review the operating environment. Next, they select the right test methods from mil-std-810. Finally, they analyze the results to see if the product meets the military standard.

Here is a simple table showing some common mil-std-810 tests:

| Test Type | Purpose |

|---|---|

| Vibration | Checks resistance to movement |

| Shock | Tests impact durability |

| Humidity | Measures moisture tolerance |

| Temperature | Assesses heat and cold limits |

Many industries rely on mil-std to improve product reliability. Companies use mil-std-810 to create rugged devices for defense, aerospace, and outdoor applications. The military standard also guides research and development for new technologies.

Mil-std continues to evolve as technology changes. Updates to mil-std-810 reflect new threats and environments. Engineers trust mil-std because it sets clear standards for durability and performance.

Why Do Manufacturers Use MIL-STD Classification?

Equipment Complies With Military Requirements

Manufacturers use MIL-STD classification to meet military requirements. Products must pass tests that match the conditions found in military operations. This process helps ensure equipment can survive in tough environments.

Contractual Requirements

Many government contracts require compliance with MIL-STD-810. Manufacturers must show that their products meet these standards before they can sell to military agencies. This requirement protects buyers and ensures quality.

Product Research and Development

Engineers use MIL-STD-810 during product research and development. Testing with a military standard helps them find weaknesses and improve designs. This process leads to stronger and more reliable products.

- MIL-STD-810 guides engineers in creating rugged devices.

- Testing early in development saves time and money.

Recognised Standard

MIL-STD-810 serves as a recognised standard across many industries. Companies outside the military also use it to prove their products are tough. Buyers trust products that meet this military standard because they know the equipment has passed strict tests.

Why Upgrade to MIL-STD-810H?

Many manufacturers now choose mil-std-810h because it offers better protection for rugged devices. The mil-std-810g vs mil-std-810h comparison shows that the newer version uses updated tests. These tests reflect real-world conditions more closely.

Mil-std-810h improves rugged performance by simulating extreme environments. Engineers use these tests to check how products handle vibration, shock, and temperature changes. This process helps companies build equipment with greater durability under harsh environmental conditions.

The mil-std-810g vs mil-std-810h debate often focuses on reliability. Mil-std-810h includes new procedures for dust, sand, and humidity. These changes help manufacturers create rugged products that last longer in the field.

Rugged devices tested under mil-std-810h perform better in challenging settings. The military standard now covers more realistic scenarios. This update supports industries that need equipment with proven rugged performance.

Manufacturers see value in mil-std-810h because it increases product lifespan. The tests identify weaknesses early in development. Companies can fix problems before products reach customers.

A simple table highlights the benefits of upgrading:

| Benefit | Description |

|---|---|

| Improved ruggedness | Handles tougher environments |

| Enhanced compliance | Meets updated military standard requirements |

| Reliable performance | Performs well in real-world conditions |

Rugged technology continues to evolve. Mil-std-810h sets a higher bar for durability under harsh environmental conditions. Manufacturers who upgrade gain a competitive edge in markets that demand tough, reliable products.

Key Technical Differences

Manufacturers often compare mil-std-810g and mil-std-810h to understand how mil-std has changed. The key differences focus on how mil-std tests simulate real-world environments. Mil-std-810h introduces new procedures that improve rugged device evaluation.

Mil-std-810g uses older test methods. These tests measure how rugged products handle vibration, shock, and temperature. Mil-std-810h updates these tests to match current field conditions.

Mil-std-810h adds more detailed steps for humidity and sand exposure. Engineers use mil-std to check how rugged devices perform in wet or dusty places. The new mil-std-810h tests help companies find weak points faster.

Mil-std-810g sometimes leaves room for interpretation. Mil-std-810h reduces confusion by providing clearer instructions. Rugged equipment tested with mil-std-810h shows improved performance in harsh settings.

The table below highlights the key differences between mil-std-810g and mil-std-810h:

| Aspect | MIL-STD-810G | MIL-STD-810H | Impact / Significance |

|---|---|---|---|

| Number of Test Methods | XX | XX | H adds more tests for comprehensive coverage |

| Temperature and Humidity | Standard requirements | Enhanced, stricter | Improves device environmental resilience |

| Vibration and Shock | G standard | H standard aligns closer to real-world use | Increases reliability |

| Test Documentation | Older procedures | More precise, traceable | Better for modern product development |

| New Test Types | None | Multiple new environmental tests | Ensures durability and lifespan |

Mil-std standards continue to evolve. Rugged products tested with mil-std-810h meet stricter requirements. These changes help manufacturers deliver better rugged devices for demanding environments.

Mil-std-810h supports industries that need reliable rugged technology. The updated mil-std tests ensure products last longer and perform well. Companies trust mil-std to guide them in building rugged solutions.

Investing in Military Standard Devices Delivers Value

Reduced Failure and Maintenance Costs

Military standard devices are tested under extreme temperature, vibration, shock, and humidity conditions. This level of testing helps identify structural and electronic weaknesses early. As a result, products that meet military standards typically experience fewer failures, lower maintenance needs, and reduced downtime throughout their lifecycle.

For industrial operations, this reliability translates into stable performance and lower total cost of ownership, especially in environments where equipment access or replacement is difficult.

Proven Performance in Real-World Environments

Military standards focus on simulating realistic field conditions rather than ideal laboratory settings. Devices tested under these standards demonstrate consistent performance in outdoor, mobile, and high-impact environments.

Industries such as manufacturing, transportation, energy, and construction rely on military standard devices because they can operate reliably under dust, moisture, vibration, and wide temperature fluctuations.

Stronger Product Value and Market Trust

Military standard compliance serves as a recognized benchmark for durability and quality. Products that meet these standards often gain higher acceptance in professional and institutional markets.

For manufacturers, investing in military standard design improves product credibility, supports tender requirements, and strengthens brand positioning in competitive markets where reliability is a key purchasing factor.

Long-Term Investment and Lifecycle Stability

Although military standard devices may involve higher initial costs, they often deliver better long-term value. Extended service life, fewer repairs, and consistent performance help offset upfront investment.

For businesses deploying equipment in harsh or remote environments, military standard devices provide a more predictable and stable operational lifecycle.

How to Choose: 810G or 810H?

Product and Environment

Manufacturers must consider the product type before selecting a mil-std version. Rugged devices designed for outdoor use need stronger protection. Mil-std-810h offers updated tests that simulate harsh conditions more accurately.

The operating environment plays a key role in this decision. Devices exposed to dust, moisture, or extreme temperatures benefit from mil-std-810h. Rugged equipment used in less demanding settings may only require mil-std-810g.

Cost vs Performance

Companies often weigh the cost of testing against the expected rugged performance. Mil-std-810h includes more detailed procedures, which can increase testing expenses.

Mil-std-810g may offer a lower-cost option for products with basic rugged needs.

A simple table can help compare the balance:

| Mil-std Version | Cost Level | Rugged Performance | Recommended Use |

|---|---|---|---|

| mil-std-810g | Lower | Standard | Mild environments |

| mil-std-810h | Higher | Advanced | Extreme environments |

Manufacturers should match the mil-std version to their budget and the rugged requirements of their products.

Certification and Market

Certification plays a major role in product acceptance. Many industries now expect mil-std-810h compliance for rugged devices.

Buyers look for products that pass the latest mil-std tests. Mil-std-810h certification signals advanced rugged performance and reliability.

Manufacturers must check market expectations before choosing a mil-std version. Rugged products with mil-std-810h certification often stand out in competitive markets.

Real-World Applications

Many industries rely on mil-std to test rugged devices. These industries include defense, aerospace, construction, and outdoor technology. Engineers use mil-std to ensure equipment performs well in harsh environments.

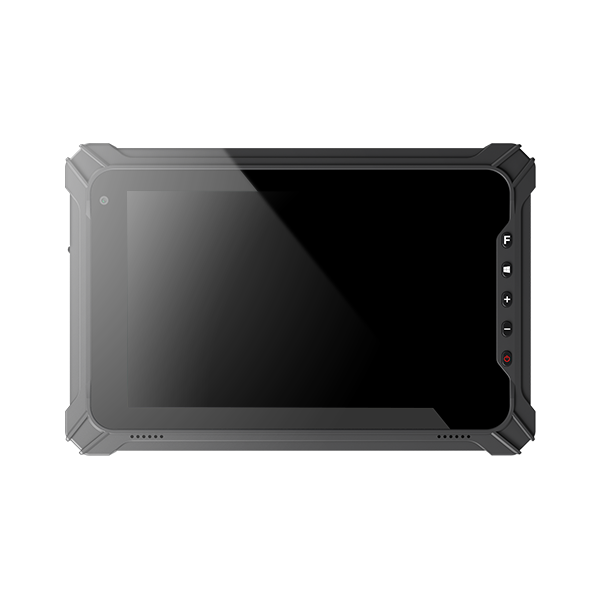

Rugged laptops and tablets often undergo mil-std testing. Workers in the field need devices that can survive drops, vibration, and extreme temperatures. Mil-std helps manufacturers design products that last longer in tough conditions.

Aerospace companies use mil-std to evaluate rugged components. Aircraft parts must withstand rapid changes in temperature and pressure. Mil-std testing ensures these parts meet strict safety standards.

Construction sites present many challenges for rugged devices. Dust, moisture, and shock can damage equipment. Mil-std testing identifies weak points and guides improvements.

Outdoor technology, such as GPS units and communication devices, benefits from mil-std evaluation. These products must operate reliably in rain, snow, and heat. Mil-std ensures rugged technology meets user expectations.

The table below shows examples of mil-std applications:

| Industry | Rugged Device Example | Mil-std Test Focus |

|---|---|---|

| Defense | Radios, sensors | Shock, vibration, humidity |

| Aerospace | Avionics, connectors | Temperature, pressure |

| Construction | Tablets, cameras | Dust, drop, moisture |

| Outdoor Tech | GPS, communication units | Rain, heat, cold |

Manufacturers trust mil-std to guide product development. Rugged devices tested with mil-std show higher reliability in the field. Mil-std continues to shape the future of rugged technology.

Conclusion

Understanding MIL-STD-810G vs MIL-STD-810H helps manufacturers and consumers select rugged devices that perform reliably under extreme conditions. While 810G provides solid testing for standard environments, 810H offers enhanced procedures that better reflect real-world stresses, improving durability, compliance, and performance. By choosing the appropriate standard, businesses can deliver longer-lasting, more dependable equipment. Embracing MIL-STD-810H ensures devices meet modern demands and maintain a competitive edge in challenging environments.

FAQ

1.What are the differences between MIL-STD-810F and MIL-STD-810G standards?

MIL-STD-810F and MIL-STD-810G are sequential versions of the U.S. military’s environmental testing standard. MIL-STD-810G introduced updated test methods, refined procedures, and expanded coverage for vibration, shock, temperature, humidity, and dust exposure compared to 810F. Devices tested under 810G reflect more realistic field conditions, offering improved durability and reliability for rugged industrial and military applications.

2.What does it mean if a device is MIL-STD-810H compliant?

A device that is MIL-STD-810H compliant has been tested according to the latest U.S. military environmental standards for ruggedness. This includes assessments for extreme temperature, vibration, shock, humidity, dust, and other harsh conditions. MIL-STD-810H compliance indicates that the equipment is built to withstand demanding environments, ensuring higher reliability and performance for industrial, defense, and outdoor applications.

3.How does MIL-STD-810H compare to IP protection ratings?

MIL-STD-810H and IP ratings measure different aspects of device durability. MIL-STD-810H tests a product’s performance under extreme environmental conditions, including vibration, shock, temperature, and humidity. IP ratings, such as IP68, focus on protection against water and dust ingress. While both indicate ruggedness, MIL-STD-810H provides a broader assessment of operational reliability in challenging industrial or military environments.

4.What is the MIL-STD-810G military-grade standard?

MIL-STD-810G is a U.S. military standard defining environmental test procedures for rugged devices. It evaluates how equipment performs under extreme conditions, including shock, vibration, temperature, humidity, and dust. Devices meeting MIL-STD-810G are considered “military-grade,” indicating enhanced durability and suitability for industrial, defense, and outdoor operations.

5.What are the differences between IP68 and MIL-STD-810H ratings?

IP68 and MIL-STD-810H ratings measure device resilience in different ways. IP68 indicates complete protection against dust ingress and continuous water immersion. MIL-STD-810H evaluates broader environmental durability, including vibration, shock, temperature extremes, humidity, and dust exposure. Devices with MIL-STD-810H compliance offer comprehensive ruggedness beyond the water and dust protection defined by IP68.