High Quality Industrial Panel PCs China Manufacturer & Supplier

Valano is a trusted manufacturer and supplier of industrial panel PCs, delivering rugged performance and reliable operation. Each unit is engineered for durability, stability, and long service life under harsh conditions.

We also provide customizable configurations to meet specific project needs. With high-quality industrial computing solutions and dedicated technical support, Valano ensures long-term supply for global buyers.

Features of Valano Panel PCs

- Industrial-grade touch screen with multi-touch support

- Fanless cooling design

- High brightness display for visibility in various lighting

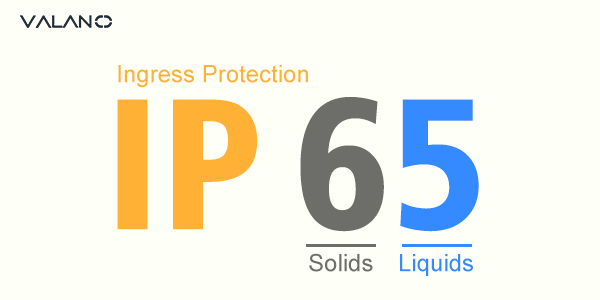

- IP65 reted dust and water resistance

- Multiple I/O ports (USB, Ethernet, serial ports)

- Robust metal housing

- Support for multiple operating systems (such as Windows/Linux)

- Long product lifecycle and availability

Valano Industrial Panel PC Series

Designed to withstand harsh conditions such as dust, moisture, vibrations, and extreme temperatures, Valano‘s IP65 fanless touch panel PCs use industrial-grade components and a sealed touchscreen interface that resists contaminants and wear.

The multi-touch screen offers responsive, accurate control, improving operator efficiency and reducing input errors. The industrial panel PCs come with a wide range of screen sizes and resolutions to fit different applications, from factory automation and process control to machine monitoring and data acquisition.

Powered by robust processors and flexible I/O options, they support various industrial communication protocols and peripheral devices, making integration straightforward. The fanless cooling reduces maintenance needs and minimizes system failures caused by dust or debris. IP65 ensures protection against water and dust ingress, extending equipment lifespan.

Advantages of Fanless, IP 65 Rated Touch Panel PC

Enhanced Durability

A fanless, IP65-rated panel PC is built for tough environments. With no moving parts like fans, it avoids dust accumulation and mechanical failure. The IP65 rating ensures resistance to water jets, dust, and oil.

Silent and Maintenance-Free Operation

Without fans, the system runs quietly and requires minimal maintenance. This design eliminates fan replacement and cleaning, reducing downtime and operational costs.

Improved Reliability in Harsh Conditions

These PCs are engineered for stable operation in environments with vibration, humidity, or temperature fluctuations. The sealed enclosure protects internal components from contaminants, extending lifespan.

Space-Saving and Flexible Mounting

Fanless touch panel PCs are typically compact and support multiple mounting options such as VESA, panel, or arm mounts. This flexibility suits confined or mobile setups.

Energy Efficiency

The absence of fans and efficient thermal design reduce power consumption. This improves energy savings, especially for continuous operation in industrial settings.

Streamlined User Interaction

The integrated touchscreen offers a simple and intuitive interface for operators. It supports real-time control, monitoring, and data visualization, enhancing productivity and user experience.

Request Pricing for Our Industrial Panel PC Needs

With factory-direct pricing, global supply, and dedicated technical support, Valano guarantees a fast response and consistent quality in every order.

Contact us today to request a quotation or discuss your project requirements — our specialists will help you select the ideal industrial panel PC perfectly matched to your application.

Industrial Panel PC Buying Guide: How to Choose the Right Model

Choosing the right industrial panel PC ensures stable performance, long lifespan, and efficiency in factory automation or industrial control systems. These devices combine a display and computing unit in one compact, rugged design. Below are the key factors to evaluate before making a purchase.

1. Environment and Durability

Start by assessing the environment where the panel PC will operate. Models with high IP ratings and fanless structures are essential for dusty, humid, or vibration-prone areas. Stainless steel housings or sealed enclosures protect the unit in industries like food processing or outdoor installations.

2. Display and Touchscreen

The screen size and brightness level determine visibility and comfort. For areas with strong lighting, choose high-brightness or sunlight-readable displays. Touchscreen types also matter — resistive screens work well with gloves, while capacitive screens provide higher precision and clarity.

3. Performance and Connectivity

Performance depends on your application. Basic HMI systems require moderate CPUs, while data analysis or automation control needs powerful processors and more memory. Check available ports such as USB, Ethernet, or serial interfaces to ensure seamless integration with existing equipment.

4. Mounting and Installation

Mounting options vary by setup. Panel-mount designs fit control cabinets, VESA mounts suit walls or arms, and open-frame units allow integration into custom enclosures. Choosing the right type ensures easy installation and stable operation.

5. Vendor Support and Customization

Reliable manufacturers provide long-term technical support, spare parts, and customization services. If your project needs special configurations, choose suppliers offering OEM or ODM options for better compatibility and flexibility.

A carefully selected industrial panel PC improves production efficiency, reduces maintenance downtime, and delivers consistent performance in industrial automation systems.

Why Choose Valano?

- User-Friendly Touch Interface: The touchscreen allows operators to interact directly with the system, eliminating the need for external keyboards or mice. High-brightness capacitive or resistive touchscreens ensure accurate operation—even with gloves or in wet and dusty conditions.

- All In One Panel PC Structure: Our integrated systems combine display, processing, and I/O ports in one compact enclosure. This reduces installation time and simplifies system architecture for industrial machine builders.

- Broad Software Compatibility: Supports Windows, Linux, and industrial software such as SCADA, HMI, MES, and IIoT platforms. Ensures seamless integration with both legacy equipment and modern smart factory systems.

- Custom Configuration: Flexible choices for CPU, RAM, storage, screen size, mounting types, and I/O configurations. Tailored to meet the technical requirements of each industrial application or project.

- Fanless Thermal Design: Passive cooling systems eliminate moving parts, preventing dust buildup and reducing failure rates. Ideal for harsh, high-vibration, or clean environments where reliability is critical.

- Long-Term Product Availability: Valano guarantees extended product lifecycles and stable component sourcing. This reduces requalification costs and helps maintain consistency across long-term deployments.

Factors That Affect the Price of Industrial Panel PCs

| Price Factor | Why It Affects Price | Typical Impact |

|---|---|---|

| Display size and type | Larger size and higher resolution cost more; touchscreen type (capacitive vs resistive) also affects price | Medium–High |

| Processor and performance | High-performance CPUs (Intel Core series) are more expensive than entry-level CPUs (Celeron/ARM) | High |

| Memory and storage | More RAM and industrial-grade SSDs increase cost | Medium |

| IP rating and enclosure | Higher IP rating (e.g., IP65) and rugged metal housing increase manufacturing costs | High |

| Connectivity and I/O options | More ports, dual LAN, PoE, expansion slots increase complexity and cost | Medium–High |

| Operating system and software | Support for Windows/Linux/Android and long-term driver support adds cost | Medium |

| Cooling and reliability | Fanless design and industrial components improve stability and lifespan | Medium–High |

| Certifications and standards | CE/FCC/RoHS and other industrial certifications require testing and compliance | Medium |

Applications of Industrial Panel PCs

IP65 protection ideal for hygienic and washdown areas, ensuring reliable dust and water resistance while supporting frequent cleaning cycles in food processing and pharmaceutical environments, and providing long-term durability in harsh, moisture-prone production settings.

Real-time control terminals for production monitoring and equipment management, providing instant data feedback, synchronized process visualization, and precise operational control across the entire factory floor to optimize workflows and minimize downtime.

Touchscreen control systems for inventory tracking and order management, enabling quick data entry, real-time stock updates, and seamless integration with warehouse and ERP systems for smoother logistics operations.

High-performance computing for image processing and defect detection, enabling fast analysis of production visuals, accurate quality inspection, and real-time feedback to reduce scrap and improve yield.

Compact, durable design for public information terminals or control stations, offering space-saving installation, reliable long-term operation, resistance to daily wear in high-traffic environments, and easy integration with existing infrastructure for consistent user access and monitoring.

Reliable operation in high-temperature or outdoor conditions, ensuring stable performance under extreme heat, direct sunlight, or harsh weather, and reducing downtime in demanding industrial environments.

Valano Touch Screen Panel PC Mounting Options

1. Desktop Mount

Used for workstations or control tables. The panel PC is placed on a stand or base for easy viewing and operation. Ideal for laboratories, production monitoring desks, and control rooms where mobility or frequent access is needed.

2. Cantilever Mount

Mounted on an arm or extension structure, allowing flexible positioning. This setup is often used on production lines, where operators need to adjust the screen angle or pull the unit closer for interaction, then push it back when not in use.

3. Wall Mount

Fixed directly on a wall or vertical surface. It saves space and keeps the workstation clean. Common in areas where equipment must stay out of the way, such as warehouses, machine rooms, or cleanrooms.

4. Louver Mount

Installed using a louvered frame, typically integrated into industrial enclosures or control cabinets. It helps with ventilation and dust protection, suitable for harsh environments where cooling and airflow are critical.

5. Embedded Mount

The panel PC is embedded flush into a control panel, machine surface, or kiosk. It offers a sleek, integrated look and prevents accidental damage. Often used in automation systems, CNC machines, and kiosks.

FAQ

What is an industrial panel PC?

An industrial panel PC is a rugged all-in-one computer that integrates a touchscreen display and computing module in a single enclosure. It’s designed for use in factories, production lines, and other harsh environments where reliability, durability, and continuous operation are essential.

What is the difference between an industrial panel PC and a regular pc?

An industrial panel PC is built for harsh operating conditions, while a regular PC is made for office or home use. Industrial models use rugged components, fanless cooling, and IP-rated protection to resist dust, moisture, vibration, and temperature changes. They can operate continuously in production lines and industrial automation systems, where standard PCs would fail quickly.

What does IP65 mean on an industrial panel PC?

The IP65 rating means the front panel is completely dust-tight and protected against low-pressure water jets. It’s ideal for environments such as food processing, packaging, and outdoor kiosks where exposure to dust or splashing liquids is common. However, IP65 usually applies to the front bezel, not the entire enclosure.

What operating systems do industrial panel PCs support?

Industrial panel PCs typically support Windows, Linux, and Android systems, depending on the processor platform. Valano offers flexible OS options to ensure smooth compatibility with PLC, MES, and SCADA software used in automation environments.

What screen sizes are available for industrial panel PCs?

What touch technologies are available?

Industrial panel PCs use either resistive or capacitive touchscreens.

- Resistive: works with gloves and styluses, suitable for industrial control.

- Capacitive: supports multi-touch and higher clarity, ideal for modern interfaces.

- Valano provides both options based on your usage scenario.

Can industrial panel PCs handle temperature extremes?

Yes. Valano’s systems operate within a wide temperature range (typically -20°C to 60°C). This makes them suitable for environments with temperature fluctuations, from refrigerated facilities to high-heat industrial workshops.

Related Articles